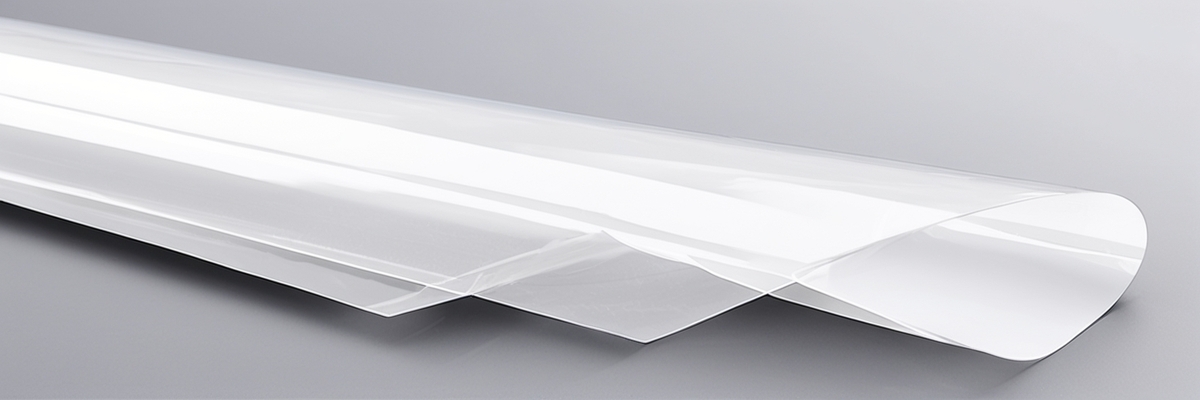

TPU film has become an indispensable high-performance material in many industries due to its excellent wear resistance. Its good elasticity, wear resistance and long life make it widely used in medical, automotive, electronics, sports equipment and other fields. By improving its molecular structure, increasing the content of hard segments, and adding fillers, the wear resistance of TPU films can be further enhanced to meet the needs of different industries. With the advancement of science and technology and the increase in demand, the application of TPU films in the wear-resistant field will become more extensive and promote the development of related industries.

Wear resistance of TPU film

Wear resistance refers to the ability of a material to maintain its shape and performance under long-term friction or wear conditions. The wear resistance of TPU film is determined by its molecular structure and material composition. The molecular chains of TPU are alternately arranged between hard segments and soft segments. The hard segments provide strength and wear resistance, while the soft segments impart elasticity and flexibility. This structure enables the TPU film to effectively absorb energy and disperse pressure when subjected to friction, thereby extending its service life.

1 TPU wear resistance mechanism

The wear resistance of TPU film comes from the balance between the rigidity and flexibility of its molecular chain. When the TPU film rubs against other surfaces, the hard segments provide pressure resistance and wear resistance, while the soft segments reduce the direct damage to the material surface caused by wear and tear by buffering friction. In addition, the elasticity of the TPU material itself can also help restore its shape and reduce the occurrence of surface damage.

The wear resistance of TPU is usually measured by indicators such as friction coefficient, wear rate and surface hardness. Research shows that TPU films exhibit excellent friction resistance under common friction and wear conditions, and can maintain good physical properties even after high-frequency friction or long-term use.

2 Factors affecting the wear resistance of TPU film

The wear resistance of TPU films is not static and will be affected by many factors, including:

Molecular weight: The larger the molecular weight, the stronger the mechanical properties and wear resistance of the TPU material.

Hard segment content: The content of hard segments determines the hardness and wear resistance of TPU. TPU films with more hard segments generally exhibit higher wear resistance.

Fillers: Fillers, such as carbon black, glass fiber, etc., are added to some TPU films during the production process. These fillers can further enhance their wear resistance.

Environmental conditions: Temperature, humidity and the characteristics of external friction materials will affect the wear resistance of the TPU film. For example, TPU's wear resistance may be reduced under high temperature conditions, while it becomes harder and more wear-resistant under low temperature conditions.