The basic steps of leather blister are as follows:

First: mold making;

2: After heating the leather product raw material to the specified temperature, place it on the mold surface, stay under the condition of vacuum suction, and form a pattern corresponding to the mold surface on the leather product raw material surface;

Thirty-three: cool the raw materials of leather products, and shape them into leather products for future use.

What kind of leather can be blistered?

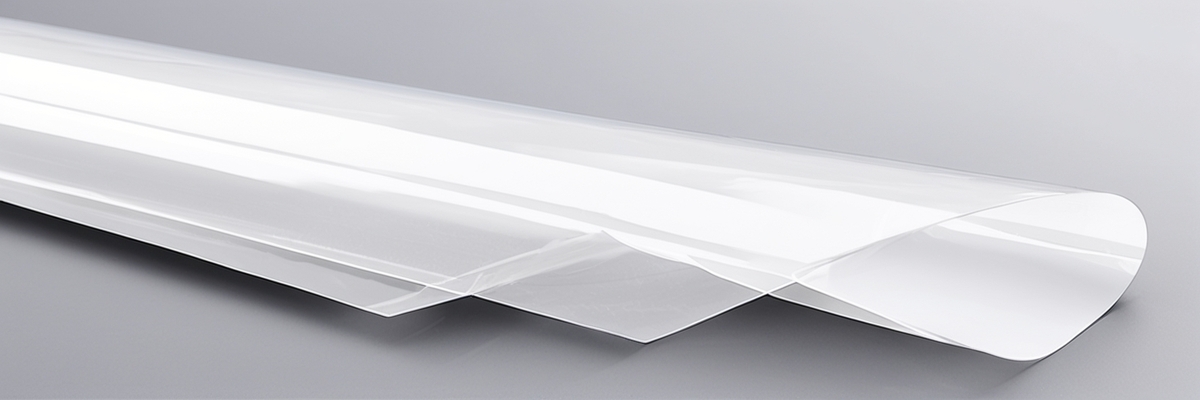

Leather is not as stretchable as plastic, so if you want to process leather with blister, you need to consider feasibility in many aspects. The raw material can be animal leather, artificial leather or composite leather. Here artificial leather is used more and the operation is simpler, mostly polyvinyl chloride (PVC) or polyurethane (PU). Composite leather includes animal leather layer and resin layer. The raw material of the resin layer is one of polyvinyl chloride (PVC) or polyurethane (PU) or polyethylene (PE) or thermoplastic polyurethane elastomer rubber (TPU film).